Spray drying machine is superior on the drying process of polymer, resinae, fuel, pigment, ceramics, glass, rust remover, insects, carbohydrate, dairy products, detergent, surfactant, fertilize, organic compounds and inorganic compounds, etc.

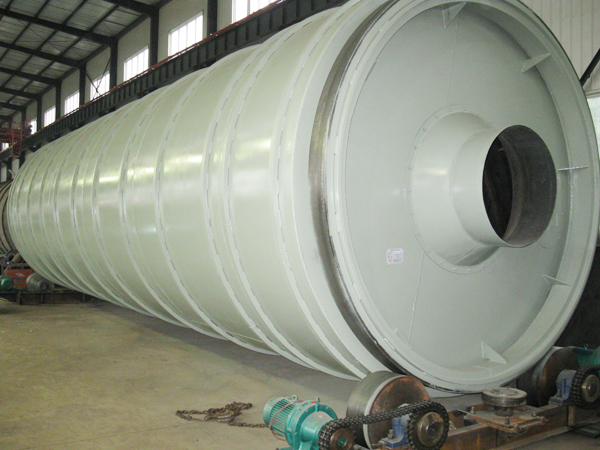

Working Diagram of Spray Drying Machine

The air enters into the air distributor on the top of the machine through the filter and heater. The hot air enters evenly at the heliciform. The liquid materials are sent to the centrifugal atomizer on the top by pump through the filter from the liquid material tank. It makes the liquid materials spray into tiny vaporific drop. The liquid materials contact with the hot air, the moisture is evaporated. In the short time, the materials are dried. The end products are discharged out from the drying tower bottom and cyclone separator, the waste gas is discharged from the fan.

Spray drying machine in the application of the chemical industry

Aluminium polychlorid

It is a kind of water purification material, inorganic polymer coagulant, it is also called polyaluminium chloride, PAC for short.. It can be divided into solid and liquid according to the form. The solid can be divided into sepia, beige, golden yellow and white according to the color. The liquid can be divided into colorless and transparent, light yellow, pale yellow and tawny.

Sodium iso-octoate

It is one of the most important varieties in the isocaprylic acid salt series products. It is widely used as drier of oil paint, printing ink, cross-linking agent of high polymer material, and heat stabilizer of plastic product. In the medicine industry, it is mainly used partial synthesis and cephalosporin antibiotics, the salt-forming agent of penicillin.