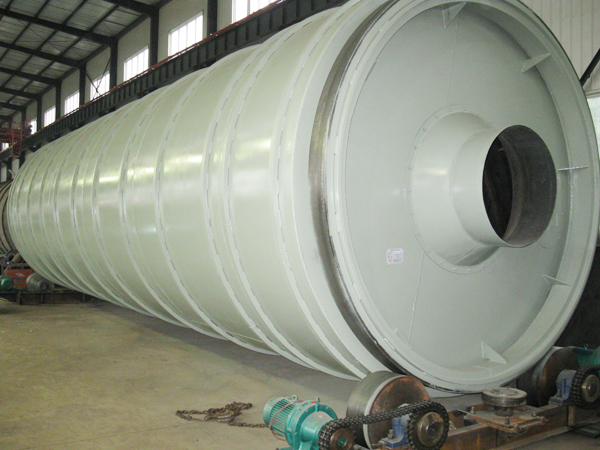

Our GC-LPG spray dryer unit is a kind of centrifugal atomizer, which has centrifugal and pressure type. It can atomized solution, suspension liquid, emulsion and slurry into small drops of liquid (surface area increased), through the hot air to dry rapidly (within a few seconds to tens of seconds), thus directly get powder products.

Raw material is throws out and atomized by centrifugal force role in rotary table (90-160 - m/s peripheral speed) from the plate edge, the whole system adopts hot air circulation drying.

Appilcationchemical industry food industry

Centrifugal (Atomizer)/Spray Dryer Working Principle Diagram

Which material can use centrifugal (atomizer) spray dryer for drying?

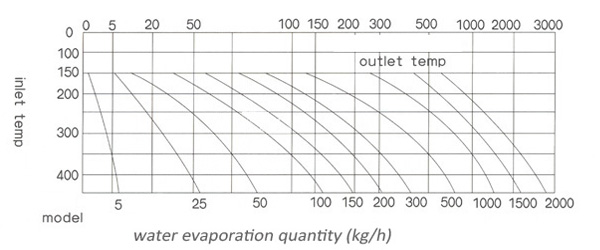

Figures of Temperature-rise and Water-evaporation

Features of High Speed Centrifugal (Atomizer)/Spray Dryer

- The drying speed is fast, and after the spraying of the liquid materials, the superficial area of the materials is increased greatly. In the hot air flow, 95-98% of water can be evaporated at a moment. The time to complete the drying just needs several seconds, that is especially suitable for the heat sensitive materials.

- This product has good uniformity, liquidity and solubleness, the product purity and quality is good, too.

- The production process is simple the operation is convenient.

- For the liquid with 40-60% of moisture content, they can be dried into powder and granular products at one time. It won’t need to be crushed or screened after the drying, which reduces the production procedures and increases the product purity. For the product grain size, bulk density and moisture content, it can be adjusted by changing the operating conditions at the certain ranges, so it is convenient to control and manage.

| Model | Inlet temperature(℃) | Outlet temperature(℃) | Max. water evaporation capacity(kg/h) | Way of atomizing | Rotation speed(rpm) | Diameter of atomizing tray(mm) | Heat supply | Max.electric heating power(kw) | Dimension(L×W×H)m | Dried power rate of recovery(%) |

|---|---|---|---|---|---|---|---|---|---|---|

| GC-LPG-5 | 140-350 automatically control | -80-90 | 5 | compressed air transmission | 25000 | 50 | electricity | 8 | 1.8×0.93×2.2 | ≥95 |

| GC-LPG-25 | 25 | mechanical transmission | 22000 | 102 | electricity +steam | 31.5 | 3×2.7×4.26 | |||

| GC-LPG-50 | 50 | 21500 | 108 | electricity +steam, fuel oil, gas | 60 | 3.7×3.2×5.1 | ||||

| GC-LPG-100 | 100 | 18000 | 108 | 81 | 4.6×4.2×6 | |||||

| GC-LPG-150 | 150 | 18000 | 150 | 99 | 5.5×4.5×7 | |||||

| GC-LPG-200-2000 | 200-2000 | 15000 | 180-340 | settled by user |

|

according to specific situations |