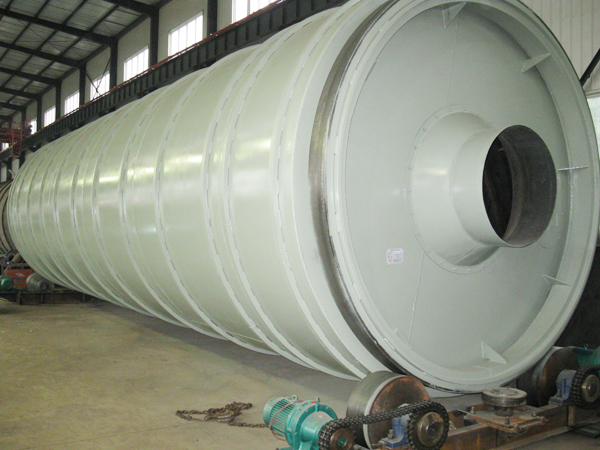

Double cone rotary vacuum dryer is a new generation design drying equipment developed by our factory.

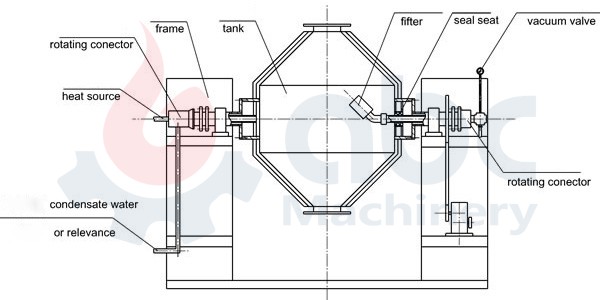

It has two kinds of connecting ways, pulley and chain. Therefore it is stable during the operation. The special design reflects the good concentricity of two shafts, the heat medium and vacuum system all adopt reliable screw joint made from abroad. On the basis, we also developed SZG-A, it not only has step-less speed regulation but also has constant temperature control.

Appilcationchemical industry food industry

Main Structure Of Double Cone Rotary Vacuum Dryer

As a professional drying equipment manufacturer, we provide hundreds of machines to the customers. These series of double cone dryer are various from high temperature heat conduction as heating medium, to mid-temperature steam and low temperature warm water. When drying the adhesive raw materials, we will design special “shoveling plate” or design balls for you.

Features of Double Cone Rotary Vacuum Dryer

- It is a new kind of drying machine integrating mixing and drying.

- Its internal structure is simple, easy cleaning, material can be taken out entirely, and easy operation.

- Reduce the labor intensity, improve the working environment.

- It has high heat-transfer coefficients, the drying rate is big, which can not only save energy, but also dry material even fully.

- It’s widely used in pharmaceutical, chemical, food, dye industries.

| Model | Working Volume(L) | Total Volume(L) | Heating Area(m2) | Speed(rpm) | Power(kw) | Height of rotating frame(mm) | Weight(kg) | Design pressure inside tank(Mpa) | Design pressure inside jacket(Mpa) |

|---|---|---|---|---|---|---|---|---|---|

| GC-SZG 100 | ≤50 | 100 | 1.16 | 6 | 0.75 | 1810 | 550 | -0.09~0.096 | ≤0.3 |

| GC-SZG 200 | ≤100 | 200 | 1.5 | 1.1 | 1910 | 700 | |||

| GC-SZG 350 | ≤175 | 350 | 2 | 1.5 | 2090 | 900 | |||

| GC-SZG 500 | ≤250 | 500 | 2.63 | 2.2 | 2195 | 1100 | |||

| GC-SZG 750 | ≤375 | 750 | 3.5 | 2.2 | 2500 | 1200 | |||

| GC-SZG 1000 | ≤500 | 1000 | 4.61 | 3 | 2665 | 1300 | |||

| GC-SZG 1500 | ≤750 | 1500 | 5.58 | 4 | 2915 | 1500 | |||

| GC-SZG 2000 | ≤1000 | 2000 | 7.5 | 5.5 | 3055 | 2000 | |||

| GC-SZG 3000 | ≤1500 | 3000 | 9.6 | 4 | 7.5 | 3330 | 3000 | ||

| GC-SZG 4500 | ≤2250 | 4500 | 13.8 | 15 | 4210 | 4000 | |||

| GC-SZG 5000 | ≤2500 | 5000 | 15.2 | 18.5 | 4500 | 4200 |