Atomizer Spray Drying Process

Spray drying is the process of producing dry powder from fluid feed by evaporating the solvent using hot gas. It is applicable in industries such as beverages, milk and egg products, pharmaceuticals, detergents, textile as well as coloring.

What’s the most important in spray drying process?

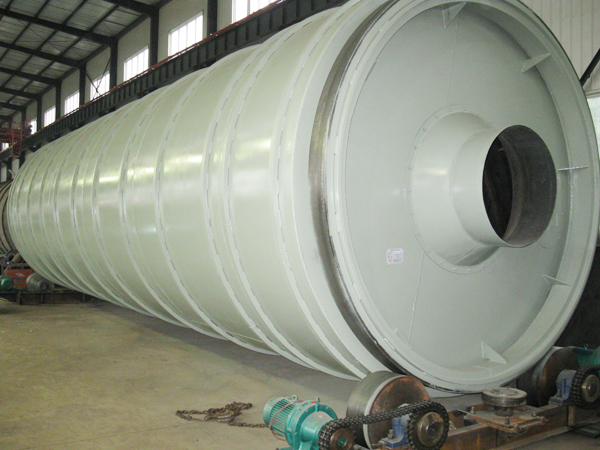

The most crucial part in the spray drying process is that of atomization. An atomizer spray dryer is an equipment used to separate solids and solutes from a product resulting in a powdered form end product.

An atomizer spray dryer is versatile and flexible to use since it can be adjusted and controlled producing products that are of high quality. The degree of atomization in an atomizer spray dryer controls powder particle properties such as surface area, density, shape, size and porosity.

Centrifugal atomization for spray drying process

The spray is created by passing the fluid in a rotary wheel and energy is provided by the atomized motor. The particle size produce will depend on the diameter of the rotary wheel. It is the most long lasting atomizer spray drying technique since it is resistance to wear and runs a long time without maintenance needs.

In conclusion, spray drying process requires an atomizer spray dryer equipment for the drying process to start. It is also vital to note that an atomizer spray dryer is the heart of the drying process since it supplies the hot chamber with the feed required to be converted into powdered form. It also determines the particle properties of the powdered product produced.