Biomass Rotary Dryer

As the focus on renewable energy sources increases, the demand for biomass fuel sources has also increased. Most of the biomass is derived from trees. However the wood harvested from trees has a high moisture content of about 45% which is too high for use as a fuel pellet. So a biomass rotary dryer will have to be used reduce the moisture content in the wood and convert the wood into a form which is suitable for making fuel pellets.

Requirement for biomass rotary dryers

It can be used to dry various biomass such as rice husks, palm fiber, wood chip, sawdust etc.

While wood from trees can be used as a fuel, there are many disadvantages due to the high moisture levels which reduces the fuel efficiency of the wood. The biomass with a high amount of water will generate less heat so a biomass rotary dryer will be required to reduce the moisture level in the biomass fuel pellets to suitable level of less than 7%. Due to the high density of water, transporting wood and biomass with high moisture levels will increase the transportation cost, as the biomass will be heavier and require more space. So it is highly recommended to use a suitable rotary dryer and reduce the moisture levels to the extent possible.

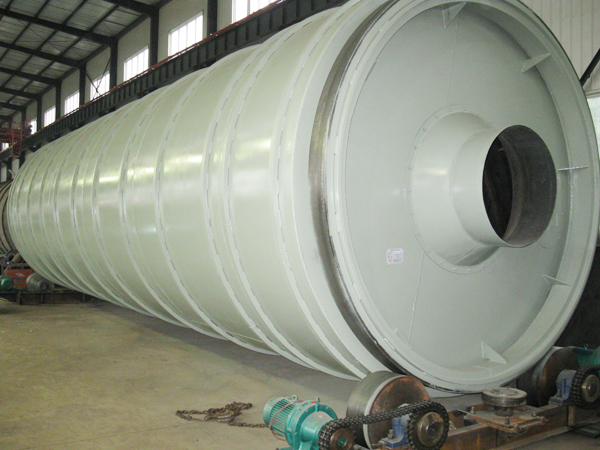

Design of the biomass rotary dryer

There are many variations in the design of the biomass rotary dryer available in the market depending on the capacity, location and investment in the dryer. It is observed that most of the dryers are using a heated process gas to increase the temperature of the biomass transferring heat, so that the moisture in the biomass will evaporate, reducing the moisture levels to the desired levels. When the biomass enters the rotary dryer, the moisture levels in the different particles may vary, however the rotary dryer is designed so that the moisture levels in all the particles are the same when these particles exit the dryer. The larger particles which usually have more moisture will spend more time in the dryer, so that most of the moisture will evaporate.

How dryers are improving biomass fuel quality

The quality of the biomass fuel depends on the thermal efficiency, the amount of heat that is generated when a particular weight of fuel is burned. High quality biomass fuel will consistently produce the same amount of energy, and have low moisture levels, low volumes.

The biomass entering the rotary dryer is handled gently, so that fines which reduce the energy efficiency are not created. The exit has a horizontal slope so that less power is required as the biomass particles move out automatically after drying.