Chicken Manure Dryer

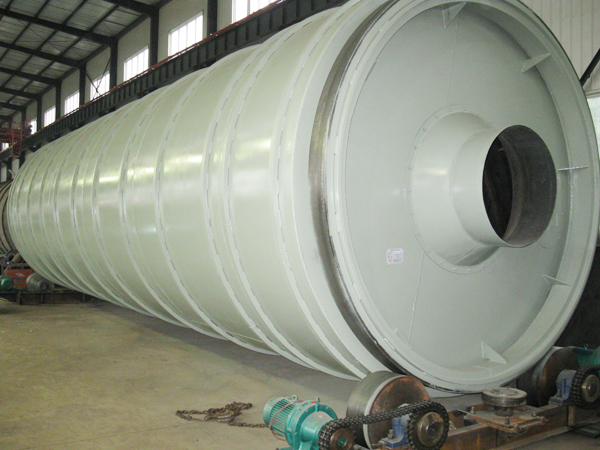

Chicken manure dryer

For the farmers who run poultry farms, a chicken manure dryer is a miraculous, problem-solving game-changer. In short, these machines are drying tunnels that remove waste from the laying boxes, passing it over fan belts and through a conveyer system which uses body heat from the chickens to dry out the muck. When the chicken manure dryer finishes a complete cycle, which usually takes about four days, it has only a 12% moisture content and is garden-ready.

How is the chicken manure dryer working principle?

The chicken manure is dropped directly into the dryer, a multi-layer system (main machine is three-layer rotary drum dryer) which allows air to get in between the layers of manure for maximum drying. The dry manure is then dropped into the pelletizing machine, a sanitizing product which holds their temperature at 70 degrees for one hour. The pellets are then bagged and sold.

How does a chicken manure dryer help a poultry farm business?

- It eliminates all of the larger problems that chicken farmers are accustomed to handling. As the moisture content is removed from the waste, the ammonia quickly dissipates, quashing smell complaints from unhappy neighbors.

- The speed with which manure is whisked away all but eliminates the opportunity for flies to lay their larvae, minimizing concerns with flies and other parasites.

- The manpower and cost associated with managing and disposing of waste is removed.

- Most importantly, though, the byproduct of the chicken manure dryer is a valuable, nutrient-rich fertilizer that can either be used on-site, defraying the cost of farm ownership, or sold to another local farmer.