How to Get Milk Powder Using A Spray Dryer

Spray drying is the process of getting powdered materials from different liquids. The technique involves rapid drying of a suspended liquid particles with a hot gas. The process is best suited for thermally sensitive materials. So, when it comes to food products, the method is too handy to turn some of them into their powdery forms. Some industrial products can also be spray dried owing to the even particle size they possess. Air is used as the heating medium in normal conditions, but for flammable and oxygen sensitive products, we got to replace it with nitrogen.

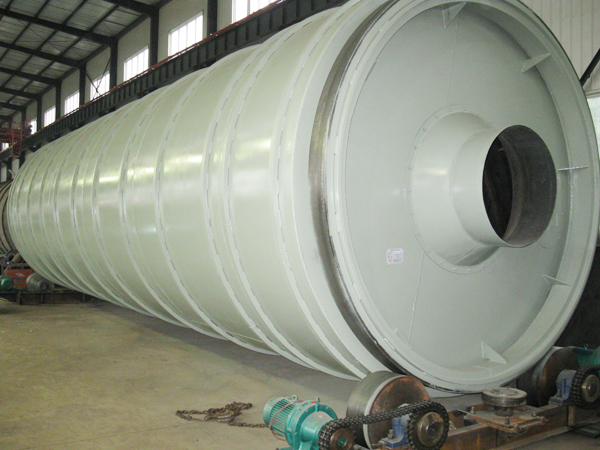

Spray dryer for milk powder

Click Now for Catalogs & Factory Price!

Dairy products have utilised the technique of spray drying to high volumes. With the advanced ideas, people felt the need to reduce the weights of different food and other products as well. This makes these products easy to carry and handle. Spray drying is the principal method employed for the production of milk powders. For getting the powder, the liquid milk is converted into a milk concentrate or suspension. This concentrate when dried with the spray of hot air, leaves behind the milk powder with subsequent evaporation and cooling.

The method of spray drying for milk powder

The process starts with setting the milk feed into the atomising device of the spray dryer. Atmospheric air is drawn and passes through a filter to the air heater and then to the air dispenser. This hot air hits the atomised droplets in the device and makes them evaporate. The hot air now cools down. A major portion of these dried outcomes slip to the bottom and enter the conveying and cooling system. The air is passed through cyclones to separate the entrapped fine particles. These particles follow others in the cooling system. The particles are collected in the pneumatic system and passed through the cyclone for separation. Finally, the air comes out through exhaust, and the powder is obtained.

Working principle of spray dryer for milk powder

Producing milk powder with a spray dryer follows the principle of atomization of the liquid concentrate. The milk concentrate is atomised in a large chamber. When the concentrate is made to pass through a hot air, the milk droplets get cooled by evaporation and never match the temperature of the air. Now, if we make the water left in a drying chamber evaporate, a fine powder is left behind with moisture content of around 5 to 6%. When the powder is made to lose more water, milk powder is obtained with moisture content 2 to 4%.