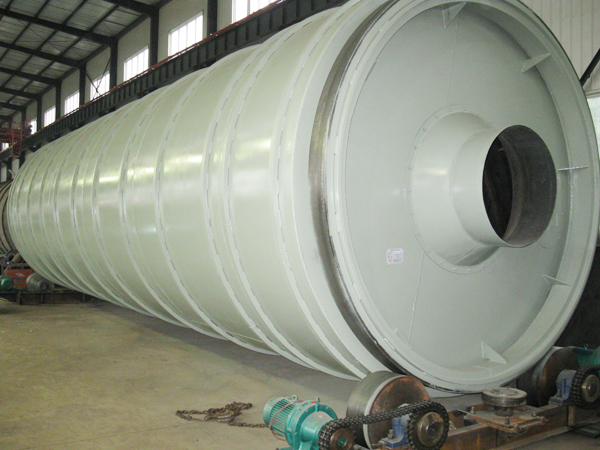

Pigment Spin Flash Dryer

We design pigment spin flash dryer for sale is a new kind of drying equipment which is developed successfully by the original flash evaporator. It adopts advanced technology, reasonable design, compact structure, wide applicable scope, large production capacity, products of good quality and high efficiency, energy saving.

Working principle of pigment spin flash dryer for sale

Advantages of pigment spin flash dryer for sale

Special cooling devices are set up at the bottom of the dryer to avoid the deterioration of the material at the bottom.

Compared with other drying methods, the proportion of materials can be increased effectively.

Special air pressure sealing device and bearing cooling device effectively extend the service life of the transmission part.

The drying chamber is equipped with graded rings and swirl films. The fineness of the material and the final moisture can be adjusted.

Application materials of pigment spin flash dryer

It can achieve material drying, crushing, screening completed by one time, eliminate the pollution of the environment, the whole machine performance reached the international advanced technology level.

Dye: anthraquinone, black iron oxide, indigo pigment, butyric acid, titanium oxide, zinc sulfide, various azo dye intermediates

Food: soy protein, gelation starch, alcohol, wheat, wheat starch

Ceramics: kaolin, silica, clay

Inorganic: boric acid, calcium carbonate, hydroxide, copper sulfate, iron oxide, barium carbonate, antimony trioxide, various metal hydride, various heavy metal salts, synthetic cryolite, etc