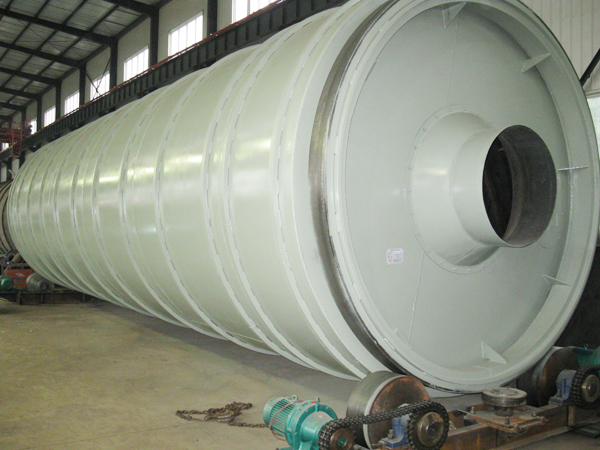

Sesame Drying Machine

Our sesame drying machine adopts automation control rotary dryer, which is special developed for high wet material and cannot be contaminated material, it has the domestic latest structure, greatly increases the thermal efficiency, higher than that of ordinary bundle dryer dry strength of 25-30%. It has already used in starch, brewing, chemical, food, medicine and other industry, and exported to Singapore, Mongolia, Russia, Malaysia, Australia and other countries.

Sesame drying machine technological conditions

- Material: sesame

- Main Equipment: rotary dryer

- Pre-drying moisture content: W1:7%

- Dried material moisture content: W2: 2%

- Throughput G: 0.5TPH

- Inlet air temperature: 80℃

- Outlet air temperature: 50℃

- Heat source: gas burner

Working principle of sesame drying

After being fed into the inlet, sesame will be evenly dispersed in the drum via shoveling plates seating on the inwall of the drum, and then sufficient contact between feedstock and concurrent (counter current) heated air will occur to expedite drying process and strength driven force. In the process, dried sesame under the combined work of tilted shoveling plates and heat current can be adjustably conveyed to the star type discharging valve at the other end of the rotary dryer.