Spray Dryer Working Principle

Spray Dryer Construction

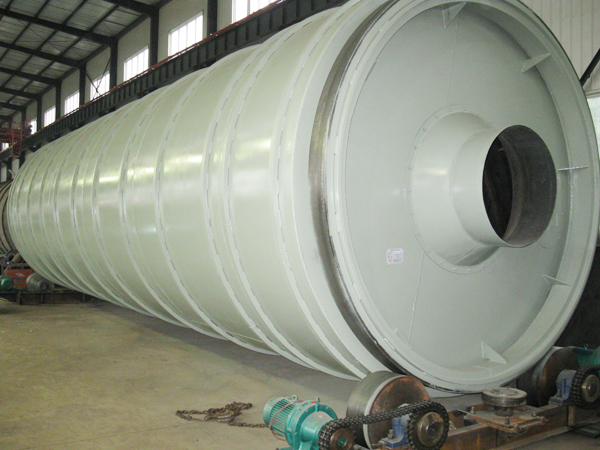

Spray dyer is composed of a huge round drying chamber with a small cone-shaped base made up of stain less steel with the size of the drying chamber variations in between 2.5 to 9 m and also elevation is 25 m or even more. The spray disk atomiser is regarding 300mm in size and also turns at a rate of 3000 to 50000 changes each minutes.

Spray drying is a one-step steady system procedure that works with fluid atomization to generate droplets that are dried to specific fragments when relocated in a warm aeriform drying form. A spray dryer is composed of a feed pump, atomizer, air heating unit, air dispenser, drying chamber and also systems for exhaust air cleansing and also powder recovery/separator.

Spray Dryer Working Principle

- In the spray dryer the liquid to be driedis atomised into the good droplets, that are tossed radially into a relocating stream of warm gas.

- The temperature level of the droplets is right away enhanced and also good droplets obtain dried instantly through round fragments.

- This proces complets in a couple of secs prior to the droplets get to the wall surface of the dryer.

In the spray dryer the fluid to be evaporated is sprayed through moisture. The min droplets are easily vaporized and also gets turned into the solid fragments, that are up to the bottom of the chamber.

The vapours are moved into the separator in which the good drying fragments that are brought together with the vapours are come apart and also gathered. Spray dryers are readily available in several types and also deigns.

A common spray dryer contain a drying chamber that is similar to the cyclone separator, so in order to make sure the very good flow of a air to facilaite heating and also mass transfer and to make sure that the dried fragments are divided by the centrifugal activity.