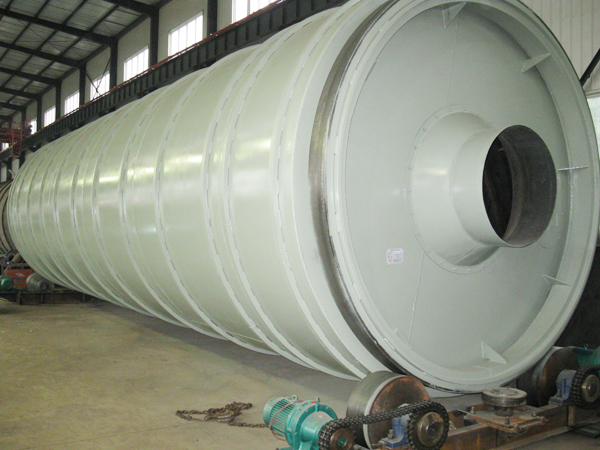

Chemical Industry Vibrating Fluidized Bed Dryer

Project description: the vibrating fluidized bed dryer is an ideal equipment to dry all kinds of crystal materials, barium sulfate, potassium nitrate…etc, compared with other drying equipment has heat source using fully, material moisture content is low, does not cause damage to the material.

Application: chemical engineering industry

What other material can vibrating fluidized bed dryer process?

Vibrating Fluidized Bed Dryer Introduction

The vibrating fluidized bed dryer adopts the excitation force produced by the vibrating motor, and the drying material, which is dry in fluidized bed surface, can be pushed forward in an orderly manner until the material is released during the drying process. During the production process, the material drying is completed in a closed state, thus reducing the cross contamination of materials and the pollution of human logistics. Linear vibration fluidized bed drying technology not only has realized the dynamic drying, than traditional static drying oven, vacuum radiation heat transfer, increase thermal efficiency and reduce process, shorten the production cycle, reduce energy consumption, and can be continuous production, achieve industrialization production.

Vibrating fluidized bed because of a wind dynamics and kinetics of thermal physics principle, make the material in a dry, due to the effect of vibration force, make the material can reach the rate of rotation and frequency of vibration friction collide with each other, not only accelerated the material internal moisture to the surface, and rotation movement of the material, can make the heat and mass transfer heat in all directions, overcome the radiation heat transfer for one-way material balance, and produce the finished product quality problems.

Features of Vibrating Fluidized Bed Dryer